Making the Most - from the Least

The weekend between Christmas and New Year's was the perfect opportunity for a couple friends to get together and get down to some serious business. My friend Big Jizzle had a 1988 Honda ZB50 project in the works, and seeing as how his loving (and completely understanding) wife, Amy, was going to be out of town that weekend snowboarding in Seattle, we decided to get the gang together for a quite possibly one of my most favorite activities ever. No, I'm not talking about shore-fishing off the Makaha coastline on the westside of Oahu, and I'm certainly not talking about hand sanding and polishing all the stainless steel hardware on one of my own bikes . . . . . I'm talking about an ENGINE BUILD.

And not just any engine build. We would be taking the venerable 49cc Honda four-stroke engine with a three speed semi-auto clutch and upgrading to a massive 124cc's, complete with a manual five speed transmission and all the requisite goodies for making this a true high performance machine!

The following is how a couple of guys spent time together, hanging out, talking life, hammering and grinding away, until on a beautiful Sunday morning, THIS was born -- and we didn't even use a blowtorch!

Big Jizzle and I got together late on a Friday afternoon to flesh out what the rough plan would be for dismantling the donor machine and creating this monstrosity. Originally, we wanted to get a headstart that evening, and finish up on Saturday afternoon. What we hadn't really considered was how much time we would spend making parts from various aftermarket companies line up, and how precise and thorough we would get while we were grinding away internal sections of the crankcase, cylinder fins, and the clutch side cover. Not to mention, between B-rad, Big Jizzy, and myself, we had far too much enthusiasm and pride to do anything less that what we felt was "the best", and that's exactly what this project deserved.

The donor bike for this project was a lightly used, 1988 Honda ZB50, which was known in Japan and Europe as the Monkey RT. It was only sold in the US in '88, but two iterations were sold overseas in '88 and '89. It is one of the few wishbone framed, horizontal four-stroke minibikes which is capable of getting a license and registration in California, and it would be a perfect starting point to initiate Jizzle's Super Minibike project. We slid across the Bay Bridge over into the Oakland Hills, and step one was to check and examine the new parts that would be going together into the new engine. Here Big Jizz is holding up a set of crankcases that had already been bored out to accept a larger cylinder and sleeve housing a 54mm piston.

J's dog, Digger, didn't really seem to care, but for J and I, this was like Christmas all over again, and we carefully sliced open the boxes containing roller rocker arms, a ported head, the 5 speed, and more. We protected the dining table with a large sheet of cardboard, and everything was looking neat and organized to start off with. Once we'd gotten a good look at the new materials, it became apparent that we'd have to rescue some parts from the old engine, and this is where the fun began. I should point out that all the new parts came via aftermarket companies located in Japan, and most of the instruction sheets and diagrams where in Japanese. Not that this deterred us, or even slowed us down at all, but the next time you hear someone say that, "This all looks Greek to me!", they may be telling the truth.

Big Jizzle's Mansion of Monkey Love is three stories tall, and this meant that all dirty work was predominantly performed downstairs in the garage, while all the fine detail work was done in the dining room, three flights of stairs up. This might not seem like much, but it would take it's toll on our team members before the weekend was out. For me, this was almost as good as it could get, because I haven't really had the time or chance to hang out with the guys and just talk motors. I don't really have the possibility of getting into anything as specialized as Monkey modification here in Europe, and the fact that I was helping J through his first big build just made it that much cooler for me. Jizz got into the swing of things by removing the tank and seat/tailsection, and I occupied myself by laying out some more cardboard and papers to rest the old engine parts on. Why is there a 10mm wrench just laying there on the floor? Because there's always a 10 mil hanging around when you don't need it, but when you DO - where the @#(*$& is it?!? It's funny, but you almost never see tools on the floor in a MotoGP garage, because we're taught to keep everything in a nice pan, or on the bench, but here in J's garage, I suppose we could let a couple things go. After all, we weren't here to race, we were here to share some time together working on something fun and light-hearted.

As stated by RAG II on Planetminis.com

"Monkey's were meant to bring happiness and laughter, they are the closest thing to fairy tail creatures that we have on this earth. You have chosen to use them for evil..." We had barely just begun!

Big Jizzle drained the oil, and we leaned the bike over a little bit trying to get every last drop out of the old engine. It was apparent that this may just have been the original oil the bike was fitted with when it was sold new, which while only having seen 1,800 miles, was still due to have been changed. 15 years ago!! Later, I would find out that J had a rear stand for the bike, something that would come in handy when we removed the footrest and kickstand assembly.

The motor started to come apart fairly easily, and for a time, things were clean and orderly :)

About this time we started getting hungry. The kind of hungry that can only be remedied by loads of oily raw fish, so we headed into town for a fantastic Sushi dinner complete with Nigori unfiltered sake (heated, because I'm a blasphemer), and cold beers. After we knocked down a ton of food, we rolled back to the house to find that Digger had expressed his desire to unwrap new toys, too. It was a clear sign that we should stop working on the 50 and start working on the 12 yr. old scotch that just happened to be laying around with our names on it.

The next morning J got up early and ran down to a bearing supply house to pick up some roller bearings we needed to run the transmission shafts in the case. I have no idea why these weren't included in the kit, and when you consider that we were spending close to Rolex money on this engine, it makes you scratch your head as to how something like this is left out of the package. When you think about it, there are about the same amount of moving parts in both a mechanical watch and a running four-stroke engine, and both are magical in that by themselves, they are inert. But add some energy, some form of fuel, and they will run and run precisely as their designers wanted. Such beautiful, intricate, little parts. This is Man-Jewelry! Fortunately for us, one of the great things about the Bay Area is that you can usually find what you need, even early on a Saturday morning. Once the bearings were in the freezer, J woke me up and we got started on figuring out how the day would go. Step one: get rid of the old gas in the tank before the acetone smell drove us bonkers in the garage. We would need all our brain cells intact, or at least reasonably intact, for the mission ahead.

Before we could begin assembling the new engine, we needed to clearance the old transmission area to accommodate five gears instead of three. About this time B-rad showed up with some true implements of destruction. Namely, his hands. Just kidding, he actually brought a bunch of necessary tools from his house in Excelsior, like a die grinder, some torque wrenches, and miscellaneous pliers that would keep us going long into the night. And I just knew that it would be a long night, because I wasn't about to quit until this engine was assembled. The gauntlet had been thrown down, and I was answering the call. Who knew when the next chance to do something like this with my boys would happen again? That's J-Bizzle, B-rad, and myself. Thanks for the use of the overshirt, B-rad, it pulled its duty several times over.

Without a doubt, the lengthiest part of this engine build was the clean and professional removal of material from the crankcases. Although I was sure no one would ever have a reason to open these cases again in the future, there was no way any of us wanted to slip up and score the case with an errant grinding tool. Bit by bit, nudge by nudge, we ground away to our heart's content. Only the harsh, shrill screaming of the die grinder made this task unpleasant. That, and the cold, wet compressed air that kept pouring out over our hands as we held the tool with a death grip that would have made Frodo and his ring proud (how's that for a NERD reference, you D&D geeks!). Jizz, please get ahold of my water trapper to go inline with your compressor, so we're not pumping moist air through our tools, and while you're at it, dig a hole in the concrete floor of the garage and bury that compressor so we never have to listen to it again. Bwahahahaha!

Big Jizzle got in on the grinding. It was a competition of comfort between his Merrell man-slippers and my Alpinestar Pit shoes. J claims that his shoes are the, "Most comfortable things ever," but I wouldn't know. I would never try on another man's shoes. Later, I threw my shoes in the washing machine to make sure all the aluminum grit and dust was cleaned out, but even so, they did stay extremely comfortable throughout the two day job, and overnight into Sunday. These are the same shoes used by the Factory Yamaha Team, and their satellite Tech 3 Team, except theirs are standard black.

Eventually B-rad had enough of just watching, and I could tell he knew what he was doing. With a look of supreme confidence, he leaned over towards Jizzle and said in his best Keanu Reeves voice, "Dude, I know what I'm doing. I know kung-fu," or something like that. Either way, B-rad Went To Town with that little die grinder, and I think the only way to describe it properly would be to say that he used it with Vigor. It was . . . inspirational, and when I would need to modify the cylinder and clutch cover later, I felt like I channeled some of B-rad's power.

It just so happened my girlfriend, Michelle, was hanging out watching us work (and taking photos), and by mid-afternoon we all decided to take a much needed break and get some burgers. Target: Berkeley! We jumped in some four-wheelers and made our way to Telegraph Ave, dodged bums on the corners, got called names by black street musicians ("Look out you big Europeans!"), and were also told to wish Baby Jesus a Happy Birthday. Once we got to Bongo Burger, it was all worth it.

We separated after eating so Michelle could go shoe shopping in the East Bay and the men could get down to doing their kind of shopping, namely going to the hardware store and buying more tools! Case in point was this beautiful drill press that came equipped with a bi-directional laser sight. We needed to drill out a space for the neutral switch we'd be installing, because we were converting these cases from CRF50, off-road model, into a street going set. Yeaaaaaah man, I'm so good with the lubricant, and B-rad was tight with the camera action. Big Jizzle was good with the second guessing, har har, but he came around.

Once the bottom end cases had been ground, drilled, and otherwise prepped for assembly, I taught J one of the most time-honored traditions in the history of man and his efforts in the home-garage. That's right - we cleared out his wife's kitchen sink and used it as our Parts Washer! There is absolutely nothing like a sink full of hot, soapy water, and a paintbrush, for cleaning out bits of this and that from engine parts! The second sink on the right was used to rinse.

B-rad's shirt came into play again when we used it to hold the cases before J blew out all the orifices with compressed air. Mmm, shiny! You'd be amazed how many people are for or against polishing the internal surfaces of their engine cases. I'll just say that it depends on the application, because there is evidence to show that it is beneficial in some cases, and not-so-gooda in others.

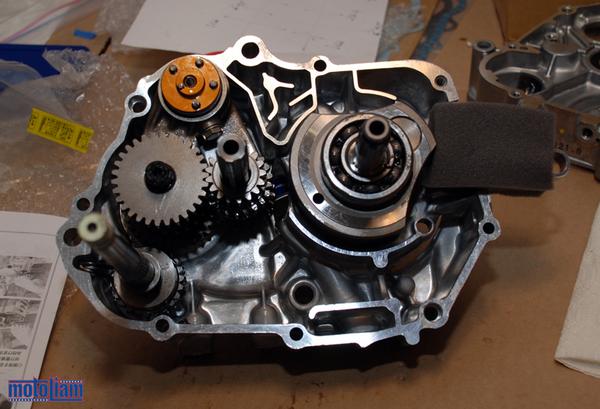

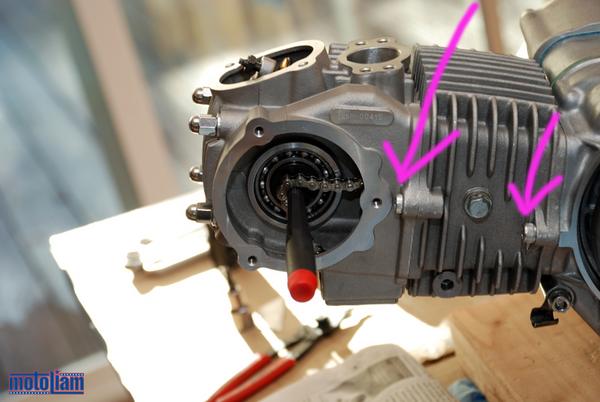

Later, this gorgeous "pork-chop" stroker flywheel assembly would be installed in the crankcases. It is more kosher than kosher. The five speed slotted in without any problems, and the kickstart assembly went together easily, too. We were rolling right along, but this was before we'd hit our second set of snags. First off, B-rad had to rush off to a dinner party back on the SF side of the bay, and secondly the clutch cover did not fit flush to the crankcases without contacting the lowest cylinder fin. To further complicate matters, the side cover featured an oil port that was directly inline with a full set of cylinder fins. Both side cover and cylinder were about to be modded, hahaha. Before we procede with the carnage, here's another shot of the "guts". Before this lightweight and moly-coated 54mm piston could be installed . . . . . . . . this cylinder needed a bunch of material removed. I have to say, this jug from Takegawa had the thickest fins I've ever seen on a mini, and grinding away the aluminum took me longer than I cared. This little styrofoam box did a good job of holding the cylinder in place as I got down to it. Once this was done, we went back to assembling the Daytona clutch on the Takegawa 5-spd. It is a really nice touch to be able to move the clutch pack from the crankshaft (right) to the primary shaft of the transmission, if only to be able to brag about rotational mass, and moreso, mass centralization. B-rad managed to come back to the house after his dinner was over, which was really nice because the team was back together. Things really started coming along at this point, but then we hit yet another snag when we realized that the Takegawa superduty kickstart shaft didn't fit perfectly through the Daytona sidecover. When last we had lined the pieces up to check for fitment, the kicker hadn't been installed, and it's just one more thing that makes you realize how many different things need to come together correctly when you're working on a project like this. It is absolutely astounding that Team KR was able to build their Honda/KR hybrids in the timeframe they had, and I take my hat off to their engineers in Banbury. After we figured out a solution that made sense to the majority of the group, B-rad had to split because it was getting pretty late into the night. We all said goodnight to the sleeping bike. Big Jizz gave me a lift into the city so I could pick up my car, my girlfriend, and most importantly, the late night snacks that would power me through until dawn - because I wasn't done yet, and neither was he, or so I thought!

Comments

One day, One day I'll find me a ZB! Great work in short time. Can't wait to see the final results.

J-BONE

Posted by: Johnny | January 14, 2008 08:33 PM

Wow,

You're back!

About time!

Looks like you had a great time back home, let's hope your effort in drinking the "mud" works. You could always cut out the smokes.

When are you off to PI for testing?

See ya,

Matt

Posted by: Matt | January 19, 2008 03:09 AM

Awesome post.

Great read, and entertaining to boot.

Best of luck this year.

Posted by: frijole | January 21, 2008 11:22 PM

A very good read once again! Hope to see pics of the final product. ;)

Posted by: BJ | March 12, 2008 08:26 AM